Industrial Robotics Safety Hazards: Mechanical, Electrical, Ergonomic, and Laser Risks

The integration of industrial robotics has transformed modern manufacturing. Automated robotic systems improve speed, consistency, and production efficiency across industries. However, alongside these advantages come serious safety risks that must be addressed through proper hazard evaluation, engineering controls, and operator training.

Under standards such as Occupational Safety and Health Administration (OSHA) regulations and American National Standards Institute (ANSI) robotic safety standards—including ANSI/RIA R15.06 and ISO 10218—employers are responsible for identifying and controlling hazards associated with industrial robots.

If these risks are not properly managed, robotic systems can cause severe injury or death.

This article outlines the primary robotics safety hazards found in industrial environments, including:

- Mechanical hazards

- Electrical hazards

- Ergonomic hazards

- Laser-related hazards in robotic cells

Understanding these risks is essential for developing a compliant robot safety program, protecting operators, and maintaining regulatory compliance.

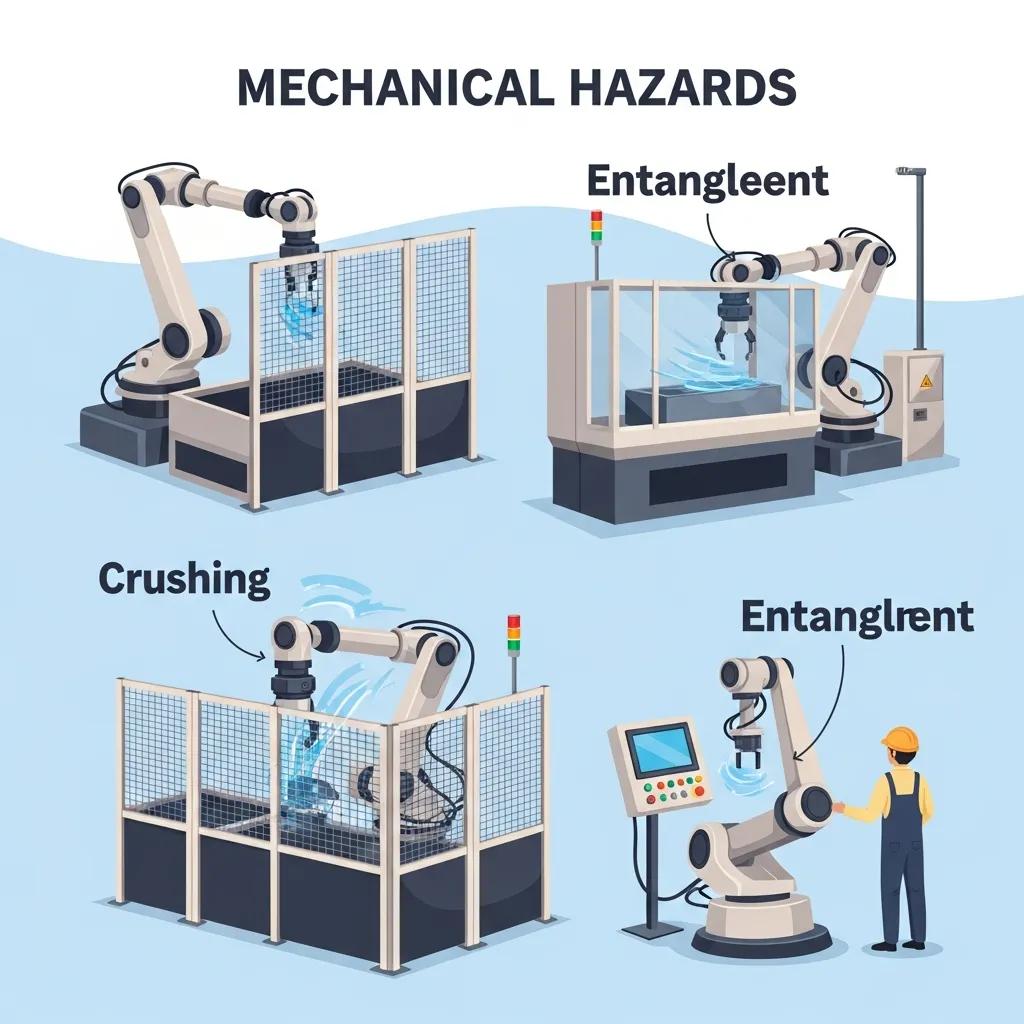

Mechanical Hazards in Industrial Robotics

Mechanical hazards are the most immediate and visible risks in robotic environments.

Industrial robots are capable of high-speed, high-force movement across multiple axes. Unlike human workers, robots do not instinctively stop when encountering resistance unless a safety function intervenes.

Common Mechanical Hazards:

- Crushing and Pinch Points – Occur between moving robot arms and fixed structures, fixtures, or other equipment.

- Impact Hazards – Caused by unexpected robot motion during automatic cycles or restart conditions.

- Entrapment – Personnel entering a robot cell without proper lockout or safety stop functions may become trapped.

- End Effector Hazards – Grippers, weld guns, cutting tools, or dispensing heads may introduce sharp edges, heat, or stored energy.

- Dropped Loads – Especially with vacuum grippers or magnetic tools if power is lost.

Mechanical hazards are particularly dangerous during:

- Programming and teaching operations

- Maintenance and troubleshooting

- Manual part loading in collaborative spaces

- Restart after protective stops

Proper safeguards such as interlocked gates, presence-sensing devices, light curtains, and safety-rated monitored stops are essential to reduce these risks.

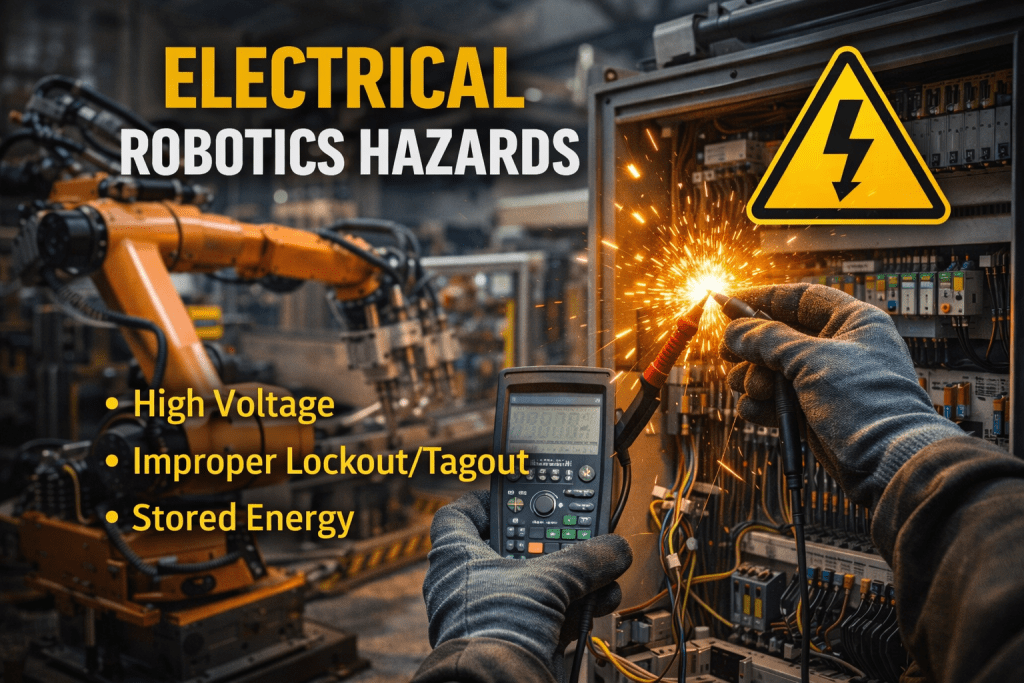

Electrical Hazards in Robotic Systems

Industrial robots rely on high-voltage power supplies, servo drives, and control panels. Electrical hazards remain present even when motion has stopped.

Key Electrical Risks:

- High Voltage Exposure – Robot controllers and servo systems often exceed 50 volts and can pose shock hazards.

- Stored Energy – Capacitors in servo drives may retain charge after power is disconnected.

- Improper Lockout/Tagout (LOTO) – Failure to follow OSHA energy control procedures can result in unexpected startup.

- Damaged Cables or Connectors – Exposed wiring increases arc flash and shock risk.

Electrical hazards are most significant during:

- Installation

- Maintenance

- Integration of peripheral equipment

- Troubleshooting inside control cabinets

Compliance with OSHA electrical standards and implementation of formal lockout/tagout procedures are critical components of robot safety certification training.

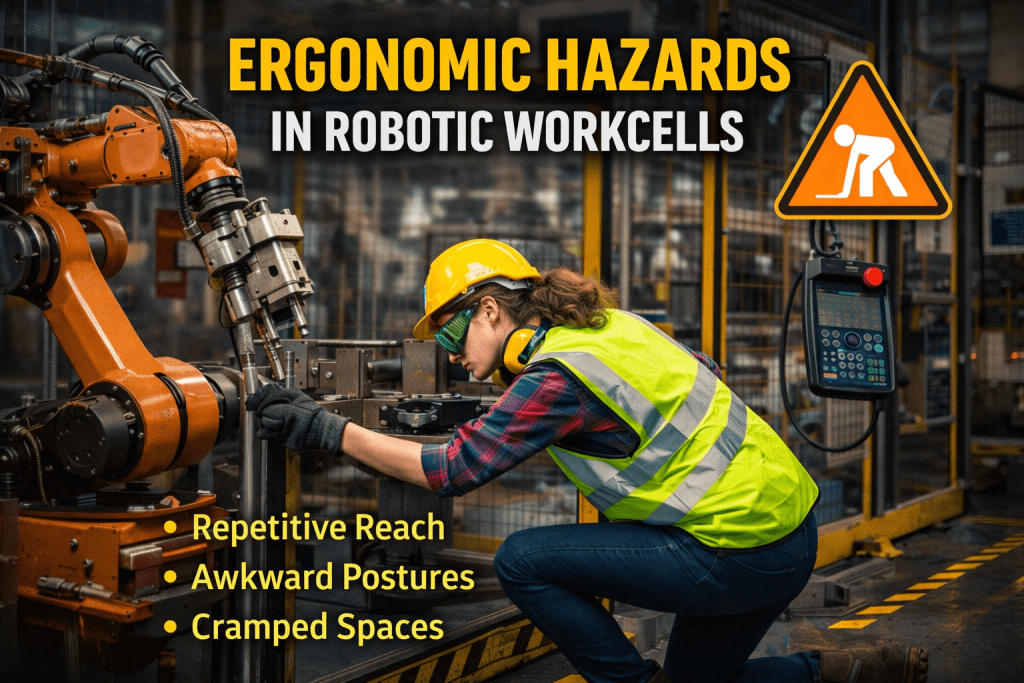

Ergonomic Hazards in Robotic Workcells

While robots reduce repetitive manual labor, they can introduce new ergonomic risks.

Common Ergonomic Challenges:

- Repetitive reaching during manual part loading

- Awkward body positioning inside robot cells

- Extended time in teach pendant programming posture

- Poor workstation layout around guarding or fencing

Over time, these factors may contribute to musculoskeletal disorders (MSDs).

A properly designed robot cell should account for:

- Safe access points

- Clear walkways

- Proper working heights

- Adequate lighting

- Minimization of awkward manual interactions

Ergonomic risk assessment is an often-overlooked component of a comprehensive robotics safety program.

Laser Safety Hazards in Robotic Environments

Many industrial robotic systems integrate high-powered lasers for cutting, welding, marking, or additive manufacturing. These applications introduce an entirely different hazard category.

Laser-integrated robotic cells must comply with ANSI Z136 standards in addition to robotic safety standards.

Laser-Specific Risks Include:

- Eye and Skin Injury from direct beam exposure

- Specular Reflection Hazards from polished metal surfaces

- Laser Generated Air Contaminants (LGAC) during cutting or welding

- Fire Hazards from high-energy beam interaction

- Invisible Infrared Radiation in industrial laser systems

In laser robotic applications, a Laser Safety Officer (LSO) may be required—particularly for Class 3B and Class 4 systems—to:

- Conduct hazard evaluations

- Establish Nominal Hazard Zones (NHZ)

- Implement engineering controls

- Approve standard operating procedures

- Ensure proper personal protective equipment (PPE)

Without proper enclosure, interlocks, and beam containment, laser-integrated robotic cells can pose extreme risk.

Why Robotics Hazard Identification Matters

Industrial robotics hazards are not limited to one category. Most incidents occur when:

- Multiple hazards overlap (mechanical + electrical + laser)

- Safeguards are bypassed

- Maintenance procedures are incomplete

- Operators are inadequately trained

- Restart conditions are not controlled

A compliant robot safety training program must address:

- Hazard identification

- Risk assessment

- Control measure implementation

- Emergency stop functions

- Safe manual operation procedures

- Lockout/tagout requirements

- Documentation and inspection protocols

Safety is not optional—it is a regulatory obligation and an operational necessity.

Final Thoughts

Industrial robotics improves efficiency, but it does not eliminate risk. Mechanical hazards, electrical dangers, ergonomic stressors, and laser radiation risks must all be evaluated and controlled under a structured robotics safety program.

Organizations that proactively implement safety standards, conduct formal hazard evaluations, and provide comprehensive robot safety certification training protect not only their workforce—but their operational continuity and legal compliance as well.

Effective robot safety is not about slowing production. It is about building a system where automation and human workers can operate safely, predictably, and in full compliance with OSHA and ANSI standards.