Understanding Laser Hazard Classifications: A Complete Safety Deep Dive

Understanding Laser Hazard Classifications: A Complete Safety Deep Dive

Introduction

Understanding how lasers are classified is the first step in building a compliant, functional laser safety program. Whether you’re managing lasers in a fabrication shop, surgical suite, or research lab, classification drives everything from training requirements to control measures. Here’s why it matters.

Why Laser Classification Matters

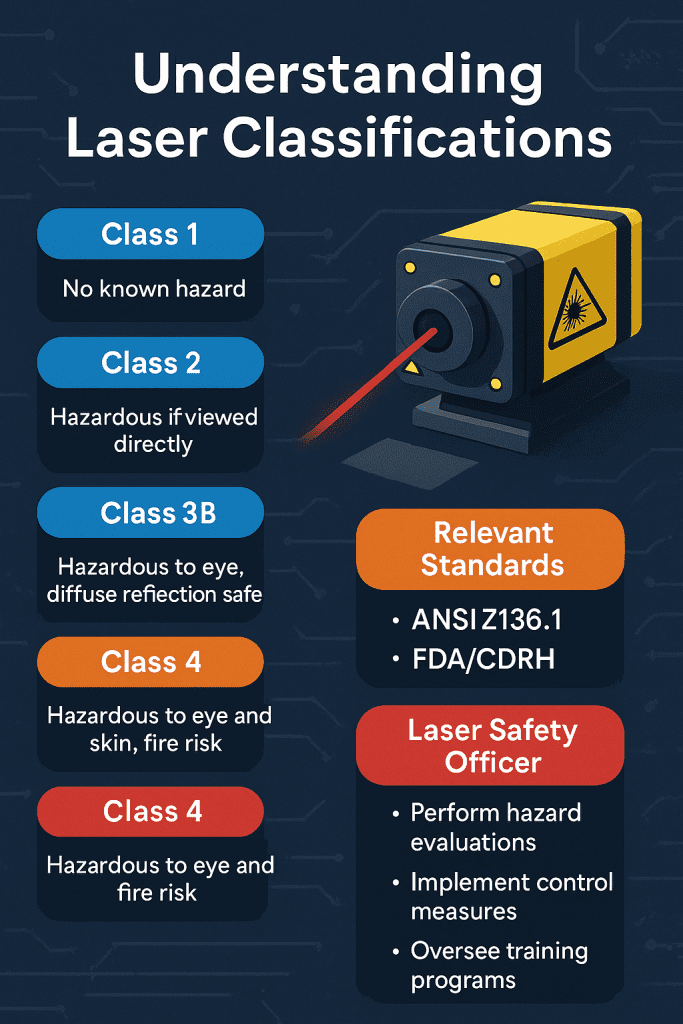

Laser classifications define the inherent risk level of a system, particularly its potential to cause eye or skin injury under normal or foreseeable use conditions. These categories—from Class 1 to Class 4—inform:

-

What kind of Personal Protective Equipment (PPE) is required

-

Whether interlocks, beam enclosures, or warning systems are needed

-

The depth of training employees must receive

-

Who may enter or operate in a Laser Controlled Area (LCA)

Laser classification is the foundation of laser risk assessment, and every safety decision starts with knowing the class.

Relevant Standards: ANSI and FDA/CDRH

Two primary regulatory frameworks shape laser classification:

-

ANSI Z136.1: The industry standard for safe laser use in the U.S., defining laser classes, safety protocols, hazard evaluations, and control measures.

-

FDA/CDRH (21 CFR 1040.10 & 1040.11): Governs product labeling and emission limits for laser manufacturers in the United States.

Together, these standards ensure both manufacturers and end users have consistent, enforceable guidelines for laser safety.

The Role of the Laser Safety Officer (LSO)

The Laser Safety Officer (LSO) is the central figure in any laser safety program where Class 3B or Class 4 lasers are used. Their responsibilities include:

-

Performing laser hazard evaluations

-

Verifying laser classification accuracy

-

Establishing appropriate engineering and administrative controls

-

Overseeing PPE selection, area signage, and training programs

-

Ensuring compliance with ANSI, OSHA, and site-specific SOPs

An effective LSO ensures that classification isn’t just a label—it’s integrated into daily operations and consistently enforced.

Why Laser Classification Matters

Laser classification isn’t just a label—it’s the foundation of every safe and compliant laser program. The classification system helps determine a laser’s potential to cause eye injury, skin damage, or secondary hazards under normal and foreseeable use. Based on factors like power output, wavelength, exposure duration, and beam accessibility, lasers are grouped into four main hazard classes: Class 1, 2, 3 (R/3B), and 4.

These classifications inform:

- Whether laser protective eyewear (LPE) is required

- The type of engineering controls (e.g., interlocks, enclosures)

- Access control and signage requirements

- The level of training operators and personnel must receive

- Whether an LSO must be appointed

Laser Classifications and Associated PPE

Here’s a breakdown of Personal Protective Equipment (PPE) requirements for each laser class:

| Laser Class | Hazard Level | Typical Applications | Required PPE |

|---|---|---|---|

| Class 1 | No hazard under normal use | Laser printers, CD/DVD drives, embedded systems | None required under normal conditions |

| Class 2 | Low hazard (visible only) | Barcode scanners, low-power laser pointers | None typically required; awareness training if exposure may be repeated |

| Class 3R | Moderate hazard | Alignment tools, laser range finders | Laser eyewear recommended for close work or intentional exposure risk |

| Class 3B | High hazard (eye risk) | Laser therapy, scientific and lab lasers | Laser protective eyewear (OD-rated), flame-resistant clothing if applicable |

| Class 4 | Maximum hazard (eye, skin, fire) | Welding, cutting, surgical lasers | LPE (OD-rated), flame-resistant clothing, gloves, face shields, respirators |

⚠️ Note: PPE must always be selected based on the specific laser wavelength and power, as required by ANSI Z136.1 and verified by the Laser Safety Officer (LSO).

Here’s your next subsection, continuing in your voice with a clear table covering training requirements, control measures, and LCA access by laser class:

Controls, Training, and Access by Laser Class

The laser classification system directly determines what kind of engineering and administrative controls must be in place. Higher-class lasers require more than just PPE—they demand interlocks, beam enclosures, access controls, and operator training tailored to the level of risk. These classifications also dictate who may enter or work within a Laser Controlled Area (LCA).

Here’s a breakdown of required safety infrastructure and training depth by class:

| Laser Class | Engineering Controls Required | Training Level | Who May Enter LCA |

|---|---|---|---|

| Class 1 | None beyond manufacturer design | General awareness (optional) | Any personnel |

| Class 2 | Warning signs if laser is accessible | Awareness training for frequent users | General access unless repeated exposure risk |

| Class 3R | Warning signs, possible beam control | Task-specific training recommended | Trained and authorized personnel |

| Class 3B | Interlocks, beam enclosures, signage, access control | Documented, LSO-led training required | Trained, PPE-equipped personnel only |

| Class 4 | Full LCA setup: interlocks, key control, beam stops, barriers | Comprehensive training, drills, SOPs | Authorized and trained only under supervision |

✅ LSO Involvement: ANSI Z136.1 requires that a Laser Safety Officer be appointed for Class 3B and Class 4 systems to ensure all training, hazard evaluations, and control measures are implemented and maintained.

Understanding these differences helps you assign access privileges, design safe workflows, and ensure training aligns with the actual hazards present in your facility.

Relevant Standards: ANSI and FDA/CDRH

Laser classification—and the safety infrastructure surrounding it—is governed by two primary regulatory frameworks in the United States: ANSI Z136.1 and FDA/CDRH regulations. While they serve different roles, together they provide a comprehensive structure for evaluating, labeling, and safely using laser systems across all industries.

ANSI Z136.1 – The Operational Safety Standard

The ANSI Z136.1 standard, is the foundational guideline for workplace laser safety in the U.S. It provides detailed direction for:

- Classifying lasers based on emission characteristics and hazard potential

- Conducting laser hazard evaluations

- Defining Maximum Permissible Exposure (MPE) and Nominal Hazard Zones (NHZ)

- Recommending engineering and administrative controls

- Outlining training requirements for all personnel

- Designating responsibilities of the Laser Safety Officer (LSO)

ANSI Z136.1 is the go-to reference for safety officers, employers, and users, especially where Class 3B and Class 4 lasers are in use.

FDA/CDRH – The Product Compliance Standard

The U.S. Food and Drug Administration’s Center for Devices and Radiological Health (FDA/CDRH) regulates laser product manufacturers through 21 CFR Parts 1040.10 and 1040.11. These regulations focus on consumer and commercial laser product safety by requiring:

- Accurate laser hazard classification

- Standardized product labeling and warning signage

- Manufacturer-provided user instructions and safety information

- Emission limit testing and documentation

This framework ensures that lasers entering the U.S. market are correctly labeled and classified according to risk, with Embedded Class 3B or Class 4 lasers being labeled as Class 1 when fully enclosed under normal operating conditions.

How They Work Together

While CDRH regulates the design and labeling of the laser product, ANSI Z136.1 governs its use in the workplace. Together, these standards ensure that:

- Manufacturers deliver compliant laser systems

- End users implement hazard controls, PPE, and training appropriate to the laser class

- Both design and operation meet enforceable safety benchmarks

In short, if you’re using a laser system in the U.S., you need both ANSI and FDA/CDRH compliance to stay safe and avoid regulatory penalties.

The Role of the Laser Safety Officer (LSO)

The Laser Safety Officer (LSO) is the designated authority responsible for the oversight, implementation, and enforcement of a facility’s laser safety program—especially where Class 3B and Class 4 lasers are present. This role is not optional for high-powered systems; it is mandated by ANSI Z136.1 and is critical to maintaining regulatory compliance and protecting personnel.

Core Responsibilities of the LSO

The LSO ensures that laser safety is embedded in daily operations, not just during training sessions or audits. Their responsibilities include:

- Laser Hazard Evaluations

Conducting assessments to determine Maximum Permissible Exposure (MPE), Nominal Hazard Zones (NHZ), and control requirements based on actual use conditions. - Laser Classification Verification

Confirming that each system’s classification matches its operational output and that any modifications don’t affect its safety rating. - Engineering and Administrative Controls

Specifying and validating safety features such as beam enclosures, interlocks, warning systems, and access controls based on laser class and use case. - PPE, Signage, and Training Oversight

Determining appropriate optical density (OD) for eyewear, ensuring signage meets ANSI standards, and coordinating initial and refresher training for all personnel. - Regulatory Compliance

Aligning all laser activities with ANSI Z136.1, OSHA, and any site-specific Standard Operating Procedures (SOPs). Also supports audits, inspections, and documentation readiness.

The LSO is the bridge between regulatory guidance and real-world implementation—ensuring that classifications, risk assessments, and safety controls are applied correctly and consistently.

LSO Responsibilities by Laser Class

| Laser Class | Is an LSO Required? | Typical LSO Involvement |

|---|---|---|

| Class 1 | No | General oversight only if embedded Class 3B/4 laser is present during service/maintenance |

| Class 2 | No (optional for training or policy) | May provide awareness training and verify signage in commercial settings |

| Class 3R | Recommended | LSO may perform hazard assessments and develop basic administrative controls |

| Class 3B | Yes – Required | Full LSO oversight of hazard evaluation, training, PPE, NHZ control, SOP enforcement |

| Class 4 | Yes – Required | Comprehensive LSO authority over all aspects of laser safety, controls, compliance, and audits |

⚠️ Note: For any operation using Class 3B or Class 4 lasers, an LSO must be appointed in writing and must have the authority to enforce safety protocol changes without approval delays.

An effective LSO program doesn’t just reduce risk—it builds trust, supports compliance, and ensures continuity in operations that depend on the safe use of high-powered laser systems.

Frequently Asked Questions

Q1: How is a laser’s classification determined?

A: Laser classification is based on the system’s output power, wavelength, beam accessibility, and exposure duration. These factors are used to assess the laser’s potential to exceed the Maximum Permissible Exposure (MPE). The result determines whether the system is classified as Class 1, 2, 3R, 3B, or 4, each with its own safety and control requirements as outlined in ANSI Z136.1.

Q2: When is a Laser Safety Officer (LSO) required?

A: An LSO is required for any operation involving Class 3B or Class 4 lasers, per ANSI Z136.1. The LSO must oversee hazard evaluations, safety training, PPE selection, and enforcement of controls. While not mandatory for Class 1–3R, LSO involvement is still beneficial for maintaining consistent oversight and documentation.

Q3: What kind of PPE is required for different laser classes?

A: PPE requirements vary by laser class:

- Class 1–2: No PPE typically required under normal operation

- Class 3R: Eye protection recommended if exposure risk exists

- Class 3B–4: Laser safety eyewear with the appropriate optical density (OD) is mandatory. Flame-resistant clothing, gloves, and respiratory protection may also be required for Class 4 systems.

Q4: Can a Class 1 laser contain a more powerful laser inside?

A: Yes. Many Class 1 systems—such as barcode scanners or enclosed cutting tools—contain embedded Class 3B or Class 4 lasers. These systems are classified as Class 1 only because their design fully restricts user access to the hazardous beam during normal operation. Maintenance or service may elevate the risk and require special procedures.

Q5: What’s the difference between ANSI Z136.1 and FDA/CDRH laser regulations?

A: ANSI Z136.1 governs the safe use of lasers in the workplace, focusing on controls, hazard evaluations, and training. FDA/CDRH (21 CFR 1040.10 & 1040.11) regulates laser product manufacturing, ensuring systems are correctly labeled and tested before sale. Together, they ensure lasers are both manufactured and used safely.

Appendix:

Below is a clear, categorized list of real-world laser examples by hazard class, aligned with ANSI Z136.1 guidance and typical use cases:

Class 1 – Inherently Safe Under Normal Use

These lasers do not exceed the Accessible Emission Limit (AEL) and pose no risk of eye or skin injury under normal operation.

- CD/DVD/Blu-ray players and drives

- Laser printers

- Laser mouse sensors

- Barcode scanners with enclosed optics

- Optical fiber inspection tools

- Encapsulated industrial systems (Class 4 lasers within a fully enclosed housing)

Class 2 – Low-Power Visible Lasers (≤1 mW)

Relies on the eye’s aversion response (blink reflex) for protection; limited to visible wavelengths (400–700 nm).

- Laser pointers (presentation tools)

- Retail barcode scanners

- Alignment lasers on construction levels

- Low-power classroom lasers or visual aids

Class 3R – Moderate Risk Visible or Near-IR Lasers (1–5 mW)

Pose a potential eye hazard under direct viewing but generally do not require complex control measures.

- Laser rangefinders

- Laser alignment tools for surveying or leveling

- Compact distance measuring devices

- Consumer-level hobbyist laser modules

Class 3B – High Risk Lasers (direct eye hazard)

Can cause immediate eye damage from direct or specular reflections; some systems may pose skin hazards.

- Low-level laser therapy (LLLT) devices

- Research laboratory lasers

- Portable spectroscopy lasers

- Small cutting or engraving lasers for plastics/metals

- Optical tweezers and fluorescence imaging tools

Class 4 – Maximum Hazard Lasers

Pose serious hazards to eyes, skin, and fire risk from direct or scattered exposure; require full control measures.

- Laser welding and cutting systems

- Surgical and dermatological lasers (CO₂, Nd:YAG, Er:YAG)

- Industrial engraving or marking lasers

- High-power research lasers (femtosecond/picosecond systems)

- Military and aerospace targeting/designation lasers

- Large-scale light shows or projection systems (if beam is audience-accessible)