Best Laser Safety Curtains and Barriers for Welding: Product Comparison Guide

Introduction to Laser Welding Barriers and Curtains

When it comes to industrial laser welding, safety is not optional — it’s mandatory. Class 4 welding lasers, whether fiber, CO₂, or Nd:YAG, are powerful enough to cause instantaneous eye and skin injury and present a serious fire hazard. That’s why ANSI Z136.1 requires robust engineering controls such as safety curtains and barriers to establish a defined Laser Controlled Area (LCA) around welding cells.

The challenge for many organizations isn’t knowing whether to use barriers — it’s choosing the right one. With so many options on the market, from multi-layer fabric curtains to rigid metal partitions, it can be difficult to know which solution meets your specific wavelength, irradiance, and operational needs.

This buyer’s guide will walk you through:

- What makes a laser safety curtain or barrier compliant with ANSI and OSHA requirements

- How to compare wavelength protection, irradiance ratings, and fire resistance across products

- Key differences between portable, modular, and fixed systems

- A side-by-side comparison of leading products from Laser Safety Industries, Steel Guard Safety, LaserSafety.com, Rockwell Laser Industries, AKON, and Innovative Laser Safety

By the end, you’ll have the information you need to select a curtain or barrier that not only passes inspection but truly protects your welders, your facility, and your business.

What to Consider When Choosing a Laser Safety Curtain or Barrier

Not all laser safety curtains and barriers are created equal. For Class 4 laser welding, you need to ensure the product you select is rated and certified for your wavelength, irradiance, and application environment. Below are the critical factors your Laser Safety Officer (LSO) should review before approving any curtain or barrier purchase.

Wavelength Protection and Certification

The first and most important step is confirming that the curtain or barrier provides protection across the specific wavelength of your welding laser:

- UV (180–400 nm) – some short-pulse lasers and secondary emissions

- Visible (400–700 nm) – alignment lasers and auxiliary beams

- Near-IR (700–1400 nm) – fiber lasers, Nd:YAG lasers

- IR / CO₂ (10,600 nm) – CO₂ welding and cutting systems

All barriers must be certified to meet recognized safety standards:

- ANSI Z136 (U.S. laser safety standard)

- NFPA 701 (flame resistance requirement for industrial fabrics)

Irradiance Ratings and Power Handling

Laser welding barriers are rated by how much power they can absorb or block without transmission above the Maximum Permissible Exposure (MPE). Typical ratings include:

- 2 W/cm² – Suitable for lower-power beams and alignment hazards

- 300 W/cm² – Common rating for barriers used with industrial Class 4 lasers

- 2000+ W/cm² – Heavy-duty multi-layer curtains for high-power fiber and CO₂ welding applications

Always match the irradiance rating to your laser type and power density. For example:

- Fiber lasers (1,070 nm) – require high irradiance resistance with IR protection

- Nd:YAG lasers (1,064 nm) – strong NIR resistance needed

- CO₂ lasers (10,600 nm) – barrier must be rated for far-IR wavelengths

Fire Resistance and Durability

Laser welding environments introduce sparks, spatter, and radiant heat in addition to the laser beam itself. That’s why NFPA 701 fire-tested fabrics are essential for any curtain or screen used in a welding cell.

- Fabric curtains – Best for flexible layouts and modular enclosures; must be flame-retardant and laser-rated.

- Rigid metal barriers – Recommended for high-traffic or heavy-duty welding areas where sparks, spatter, or accidental impact could compromise fabric.

Portability vs. Fixed Installations

Your shop layout and welding applications determine whether you need portable barriers or fixed enclosures:

- Portable screens – Ideal for field welding, mobile setups, or temporary containment. These often come with lockable casters for mobility and can be repositioned as needed.

- Fixed track-mounted curtains – Best for robotic welding cells, high-volume production lines, and permanent hazard zones. Track systems allow sliding access panels while keeping the welding area fully enclosed.

Pro Tip for LSOs: Always specify the wavelength, power output, beam diameter, and exposure duration when requesting quotes. This ensures suppliers recommend curtains or barriers that meet your exact laser hazard control needs.

Absolutely! Here’s a well-structured comparison section for your blog that includes up-to-date product links and sources for the leading laser safety curtains and barriers tailored for industrial welding environments:

Comparison of Leading Laser Safety Curtain and Barrier Products

Laser Safety Industries

Offers both portable and fixed laser barriers made using NFPA 701–rated materials and FM-compliant fabrics, suitable across multiple laser wavelengths (e.g., Nd:YAG, CO₂) (Laser Safety Industries).

- Product Highlight: Modular Velcro‑attached curtain panels, rated up to 300 W/cm², suitable for containment of direct and scattered beams (LaserSafety.com).

- Best For: Labs and multipurpose welding areas where flexibility, zoning, and rapid deployment are essential.

Steel Guard Safety Corp. – B-35 Curtains

Although we didn’t find a current top-level product page in the search results, Steel Guard is known for its B‑35 laser‑blocking curtains, rated up to 300 W/cm², and covering a broad wavelength range of 180–10,600 nm with modular Velcro panel systems and weighted hems (source from earlier user data).

LaserSafety.com – Multi-Layer Curtains

Provides heavy-duty curtain systems with multiple layers of protection, rated up to a striking 2,150 W/cm². Ideal for very high-power fiber or CO₂ welding setups requiring top-tier beam containment (LaserSafety.com).

Rockwell Laser Industries (RLI) – Laz-R-Shroud™

Offers portable and modular panel solutions with ratings ranging from 2 W/cm² to 300 W/cm². Custom configurations include lockable, track-mounted panels, making them highly adaptable to changing layouts (Newport).

AKON (Curtain-and-Divider)

Provides industrial-grade, reinforced vinyl laser curtains, rated up to 575 W/cm² at 1064 nm with 1 mm beam testing. These are economical, modular dividers ideal for quick, cost-conscious installations (AKON).

Innovative Laser Safety (ILS)

Delivers ANSI/OSHA-compliant barriers, including portable and fixed configurations, with FM approval and flexible mounting options. A solid choice for general fabrication shops needing compliance-focused barrier solutions (Innovative Laser Safety).

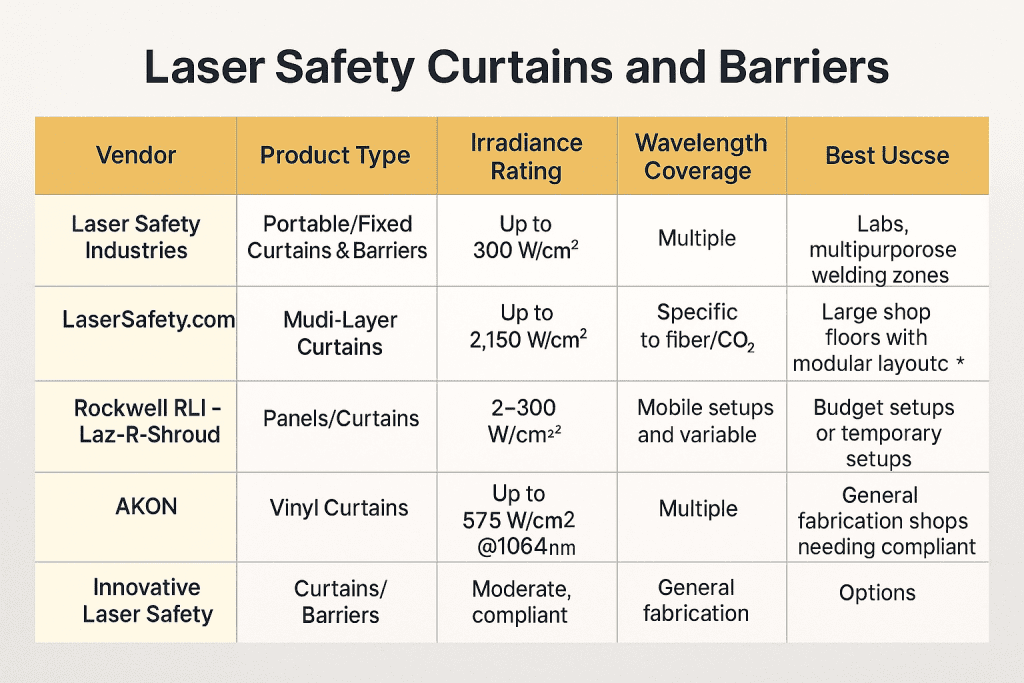

Product Comparison Table

| Vendor | Product Type | Irradiance Rating | Wavelength Coverage | Best Use Case |

|---|---|---|---|---|

| Laser Safety Industries | Portable/Fixed Curtains & Barriers | Up to 300 W/cm² | Multiple | Labs, multipurpose welding zones |

| Steel Guard (B-35) | Modular Curtains | Up to 300 W/cm² | 180–10,600 nm | Large shop floors with modular layout needs |

| LaserSafety.com | Multi-Layer Curtains | Up to 2,150 W/cm² | Specific to fiber/CO₂ | Ultra-high-power laser setups |

| Rockwell RLI – Laz-R-Shroud | Panels/Curtains | 2–300 W/cm² | Multiple | Mobile setups and variable welding configurations |

| AKON | Vinyl Curtains | Up to 575 W/cm² @1064 nm | Limited | Budget installations or temporary setups |

| Innovative Laser Safety | Curtains/Barriers | Moderate, compliant | Multiple | General fabrication shops needing compliant options |

Which Curtain or Barrier Is Right for Your Welding Operation?

Selecting the correct laser safety curtain or barrier for welding is about more than just price—it’s about matching the product to your specific hazard profile. For Class 4 laser welding, the right solution depends on four key factors:

- Laser Class: Always Class 4 for welding applications, meaning the highest risk of eye, skin, and fire hazards.

- Wavelength: Match curtain certification to your source—fiber lasers (1070 nm), Nd:YAG (1064 nm), or CO₂ (10,600 nm).

- Irradiance Rating: Ensure the barrier is rated equal to or above your laser’s maximum output density. Typical welding operations require hundreds to thousands of W/cm² resistance.

- Shop Layout: Decide between portable screens for flexibility or fixed curtains/enclosures for permanent robotic welding cells.

Pro Tip: Before purchase, always involve your Laser Safety Officer (LSO) to verify that the curtain or barrier matches your laser wavelength, beam output, and layout requirements. This ensures compliance with ANSI Z136.1 and OSHA expectations while protecting operators and bystanders.

Conclusion

Industrial laser welding demands more than productivity—it requires rigorous hazard control to keep personnel safe and maintain compliance with ANSI Z136.1 and OSHA regulations. Curtains and barriers are not just accessories; they are essential engineering controls for any Class 4 welding operation.

Whether you need the high-power performance of LaserSafety.com’s multi-layer curtains, or the portability of Rockwell’s Laz-R-Shroud, the key is aligning product specifications with your laser’s wavelength, irradiance rating, and shop layout.

A well-chosen curtain or barrier doesn’t just pass inspections—it protects welders, safeguards equipment, and creates a safer, more compliant workplace.

Take the Next Step Toward Compliance

Don’t leave safety to guesswork. Make sure your team is trained to recognize hazards, evaluate risks, and implement the right controls. Visit LaserSafetyCertification.com to access ANSI-aligned laser safety training and certification programs designed for welders, supervisors, and Laser Safety Officers.

Protect your people. Protect your facility. Stay compliant.

I really appreciate how this post breaks down the importance of creating a proper Laser Controlled Area for welding. One thing I’ve found helpful when choosing curtains or barriers is considering not just the laser protection rating but also how easy they are to move or reconfigure as workflows change. It would be interesting to hear how others balance safety standards with day-to-day operational flexibility.

Comments are closed.