Industrial Robt Safety Certification

What does it mean to be OSHA Compliant?

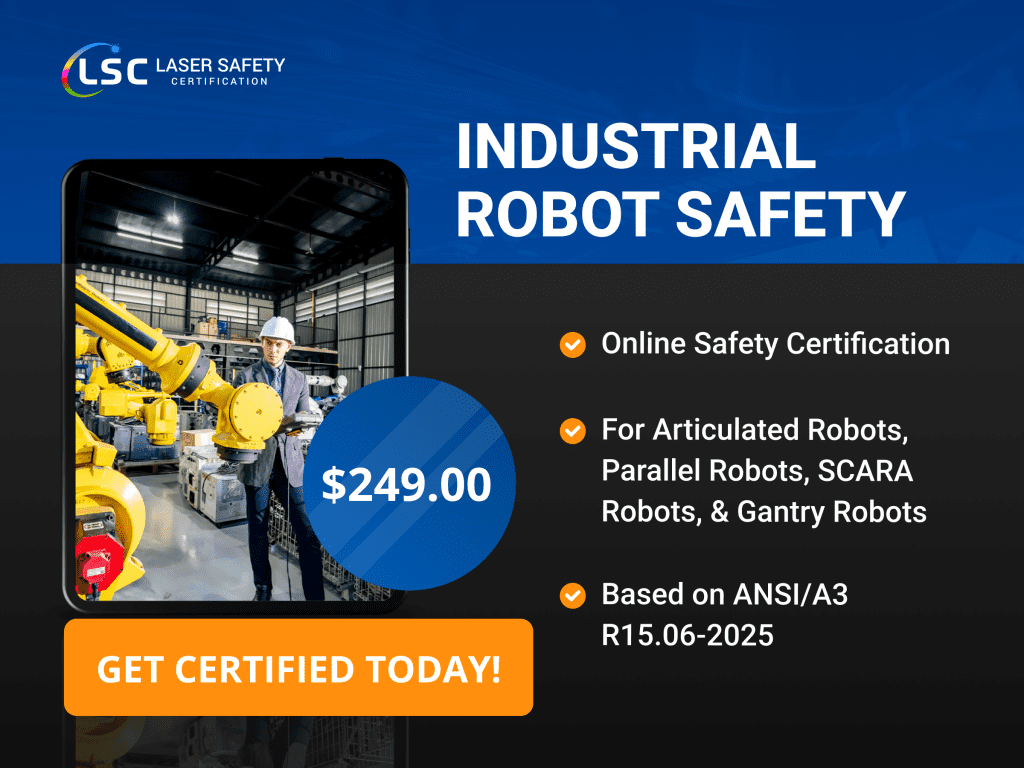

Industrial Robot Safety Certification - $249

Through our Industrial Robot Safety Curriculum, your employees will learn everything they need to know about the following:

- Robot Hazards

- Safety Functions

- Force Testing

- Robot Cells

- Robot Integration

- Pre-Commissioning

- Control Functions

- Safe Robot Operation

- Safeguards

- Commission Validation

- End-Effectors

- Collaborative Spaces

- Stop Functions

- Manual Part Loading

- Material Entry/Exit

- Documentation

Being robot safety certified means more than sitting through a training video or checking a compliance box. It means an individual has completed structured, role-appropriate training that proves they understand how industrial robots actually create risk—and how to control that risk before someone gets hurt. This certification confirms the person can recognize hazardous robot motion, understand the purpose and limitations of safeguarding systems, and follow proper procedures during operation, setup, maintenance, and troubleshooting. In real terms, robot safety certification demonstrates that a worker knows how injuries occur in automated environments and how to prevent them by applying established safety principles, standards, and best practices throughout the life of a robotic system.

Key Components of Robot Safety

for Industrial Automation Applications

Regulatory Compliance

OSHA Standards: Knowledge of relevant OSHA regulations and guidelines related to robot safety.

ANSI/RIA R15.06 regulations detail specific training protocols for operating safely around industrial automated robot equipment.

ISO 10218 is the international standard by which all manufactures and operators must comply.

Certification Process

How to get certified for laser safety

Certification Benefits

Why it is important to become laser safety certified

Responsibilities of Certified Technicians/Operators

What is your role after becoming certified?

-

Identify robot-related hazards, including unexpected motion, stored energy, and end-effector risks

-

Verify that safeguarding devices, interlocks, and emergency stop functions are installed and functioning properly

-

Follow and enforce approved operating, programming, and maintenance procedures

-

Ensure manual tasks and collaborative operations are performed within defined safety limits

-

Respond appropriately to abnormal conditions, faults, and emergency stop events

-

Support risk assessments, incident investigations, and ongoing safety improvements within robot workcells

Summary

Being robot safety certified as an Industrial Robot Safety Technician or Operator means completing formal, role-specific training, passing a certification exam, and demonstrating the knowledge required to work safely around robotic systems. This certification validates the individual’s understanding of robot hazards, safeguarding methods, safety functions, applicable standards, and emergency response procedures—making them a critical part of maintaining a safe and compliant automated work environment.