What are my Duties as a Laser Safety Officer?

What Are My Duties As A Laser Safety Officer?

Laser Safety Officers (LSOs) play a crucial role in ensuring safe use of lasers and compliant use across various industries. From healthcare and manufacturing to research and development, LSOs are responsible for implementing and maintaining comprehensive laser safety programs that protect employees, patients, and the general public from potential laser hazards.

Overview of a Laser Safety Officer’s Role

The primary role of an LSO is to oversee all aspects of laser safety within an organization. This includes developing and implementing laser safety policies, conducting risk assessments, providing training to personnel, and ensuring compliance with relevant regulations and standards, such as those set by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). Each company is responsible for administering their own Laser Safety Program in-house, and our certification course will teach you everything you need to do so.

LSOs must thoroughly understand laser physics, the biological effects of laser radiation, and control measures to identify and mitigate laser hazards effectively. They collaborate with various departments and stakeholders to create a culture of laser safety and continuously improve safety practices.

To become a qualified LSO, individuals often pursue specialized training and certification. LSO Certification Online programs provide comprehensive courses that cover the essential knowledge and skills required for the role, enabling professionals to demonstrate their expertise and commitment to laser safety.

Laser Safety Officer Requirements

Becoming a Laser Safety Officer (LSO) involves meeting specific regulatory agency and industry standards. These requirements ensure that LSOs are well-equipped to manage laser safety programs effectively and maintain a safe working environment for all personnel.

OSHA Requirements

The Occupational Safety and Health Administration (OSHA) has established workplace laser safety guidelines. According to OSHA, employers are responsible for providing a safe and healthful work environment, which includes protecting employees from laser hazards.

OSHA standards, such as the General Duty Clause (Section 5(a)(1) of the OSH Act), require employers to identify and control laser hazards. Compliance with OSHA regulations is essential to avoid potential fines and legal liabilities and, most importantly, to ensure the safety and well-being of employees.

LSO Responsibilities

An LSO’s primary responsibilities include:

- Developing and implementing a comprehensive laser safety program

- Conducting thorough risk assessments to identify potential laser hazards

- Establishing and enforcing laser safety policies and procedures

- Providing laser safety training and education to employees

- Ensuring that laser equipment is appropriately classified, labeled, and maintained

- Investigating laser incidents and accidents and implementing corrective actions

- Maintaining accurate records of laser safety activities and compliance

To learn more about the specific roles and responsibilities of an LSO, visit our blog post, “What is an LSO?”

Fulfilling these responsibilities requires technical expertise, communication skills, and leadership abilities. LSOs must stay up-to-date with the latest laser safety standards and best practices to ensure ongoing compliance and continuous improvement of their organization’s laser safety program.

Laser Safety Checklist OSHA

Laser Safety Officers (LSOs) must follow a comprehensive laser safety checklist to ensure compliance with OSHA regulations and maintain a safe working environment. This checklist should cover all aspects of laser safety, from identifying potential hazards to implementing appropriate control measures and providing necessary training.

Laser Hazards and Safety Measures

Identifying potential laser hazards is the first step in developing an effective laser safety program. LSOs must assess the risks associated with each laser system, considering factors such as laser class, wavelength, power, and application.

Once hazards are identified, LSOs should implement appropriate safety measures to mitigate risks. These measures may include:

- Engineering controls (e.g., protective housings, interlocks, beam stops)

- Administrative controls (e.g., standard operating procedures, access restrictions)

- Personal protective equipment (PPE) (e.g., laser safety eyewear, protective clothing)

Regularly reviewing and updating safety measures is crucial to maintaining a safe work environment as laser technologies and applications evolve.

OSHA Laser Safety Training Requirements

OSHA requires employers to provide adequate training to employees who work with or around lasers. LSOs ensure that all personnel receive appropriate laser safety training based on their roles and responsibilities.

OSHA’s training guidelines include:

- Initial training for new employees or those assigned to laser-related tasks

- Refresher training at regular intervals or when changes in laser equipment or procedures occur

- Hands-on training for employees who operate laser systems

- Training on the proper use and maintenance of PPE

LSOs should maintain accurate records of all laser safety training sessions, including attendees, dates, and topics covered.

ANSI Laser Safety

The American National Standards Institute (ANSI) has developed the ANSI Z136 series of standards for laser safety. These standards provide detailed guidance on laser hazard classification, control measures, and safety program management.

ANSI Z136.1, the primary standard for laser safety, is widely recognized and adopted by industries and regulatory agencies, including OSHA. LSOs should be well-versed in ANSI Z136 standards and ensure their organization’s laser safety program aligns with these guidelines.

All of the Laser Safety Certification courses we offer are both OSHA and ANSI compliant, with reference to ANZI Z136.1 & Z136.3

Integrating ANSI laser safety standards with OSHA requirements creates a comprehensive framework for managing laser hazards and maintaining a safe working environment. By following this laser safety checklist and staying current with OSHA and ANSI guidelines, LSOs can effectively protect employees and maintain compliance.

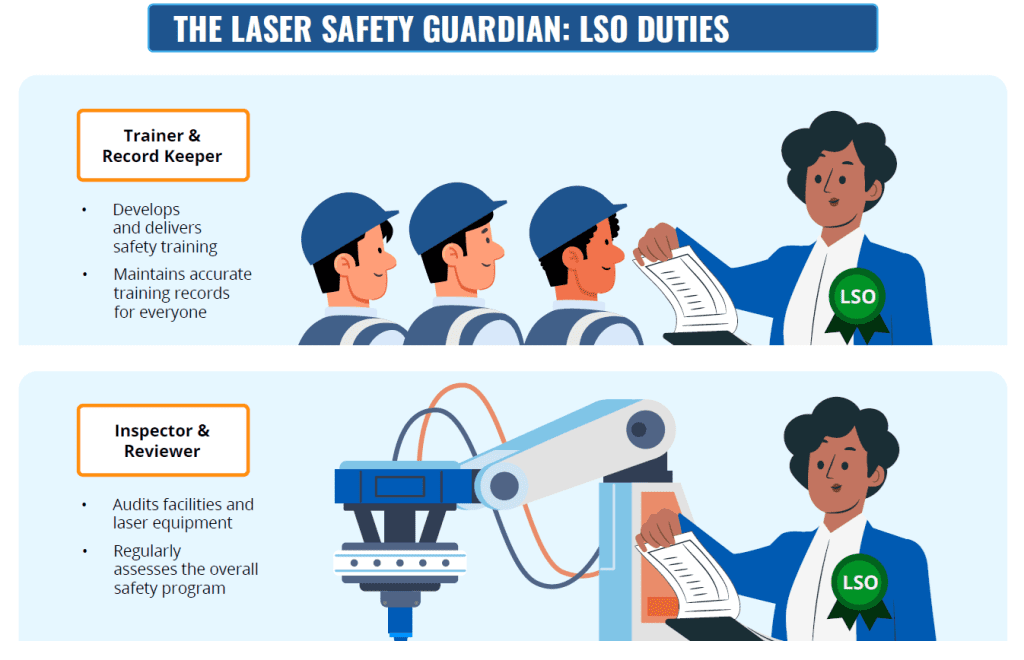

Essential Duties of a Laser Safety Officer

Laser Safety Officers (LSOs) have a multifaceted role in ensuring the safe and compliant use of lasers within their organization. Their essential duties encompass developing and implementing safety policies, conducting regular audits and inspections, and providing comprehensive training and education to staff.

Developing and Implementing Safety Policies

One of an LSO’s primary responsibilities is creating comprehensive laser safety policies tailored to their organization’s specific needs. These policies should be based on a thorough understanding of laser hazards, regulatory requirements, and industry best practices.

When developing safety policies, LSOs should consider factors such as:

- Laser classification and hazard identification

- Control measures and personal protective equipment (PPE)

- Standard operating procedures (SOPs) for laser use and maintenance

- Emergency response and incident reporting protocols

Once safety policies are established, LSOs must ensure that all personnel adhere to these protocols. Regular communication, training, and enforcement of consequences for non-compliance are essential to maintain a strong safety culture.

Conducting Safety Audits and Inspections

To maintain a safe working environment and identify potential areas for improvement, LSOs must conduct regular safety audits and inspections. These assessments should cover all aspects of laser operations, including equipment maintenance, control measures, and employee compliance with safety protocols.

During audits and inspections, LSOs should:

- Verify that laser equipment is appropriately classified, labeled, and maintained

- Ensure that appropriate control measures and PPE are in place and functional

- Observe employee behavior and adherence to safety procedures

- Document any safety issues or non-conformances and develop corrective action plans

Regularly scheduled audits and inspections help LSOs proactively identify and address safety concerns before they lead to accidents or injuries.

Training and Educating Staff

Continuous staff training and education are crucial to a successful laser safety program. LSOs are responsible for developing and delivering comprehensive training programs that cover all aspects of laser safety relevant to their organization.

Effective training programs should include:

- Initial training for new employees or those assigned to laser-related tasks

- Refresher training at regular intervals or when changes in laser equipment or procedures occur

- Hands-on training for employees who operate laser systems

- Training on the proper use and maintenance of PPE

LSOs should employ best practices for adult learning, such as interactive exercises, case studies, and practical demonstrations, to ensure that training is engaging and effective. Maintaining accurate records of training sessions and employee participation is also essential for compliance and continuous improvement.

To learn more about the path to becoming an LSO and the responsibilities involved, visit our blog post, “How to become an LSO.”

FAQ Section

Are you required to have a laser safety officer?

According to the American National Standards Institute (ANSI) Z136.1 standard, any facility that uses Class 3B or Class 4 lasers or laser systems must designate a Laser Safety Officer (LSO). The LSO oversees safety during all operational, maintenance, and servicing situations involving these high-powered lasers. The designated LSO should have the authority and responsibility to monitor and enforce the control of laser hazards within the facility.

What is the first rule of laser safety?

The cardinal rule of laser safety is to never, under any circumstances, look directly into a laser beam. Looking directly into a laser beam can cause severe eye damage, including retinal burns, cataracts, and even permanent blindness. To protect the eyes from laser hazards, it is crucial to use appropriate personal protective equipment (PPE), such as laser safety eyewear, and to follow all safety procedures and control measures established by the LSO and the organization’s laser safety program.

Protect Your Workforce and Ensure Compliance with Laser Safety Certification

Ensuring Compliance with Laser Safety Certification

Laser Safety Certification (LSC) offers comprehensive certification programs to equip Laser Safety Officers (LSOs) with the knowledge and skills to manage laser safety in their organizations effectively. Our courses cover many topics, from laser physics and hazard analysis to safety program development and regulatory compliance.

By enrolling in LSC’s certification programs, you can:

- Gain a thorough understanding of laser safety principles and best practices

- Learn how to identify and mitigate laser hazards in various settings

- Develop the skills to create and implement effective laser safety programs

- Stay current with the latest industry standards and regulations

- Demonstrate your commitment to laser safety and professional development

Our experienced instructors, interactive learning modules, and practical exercises provide an engaging and effective learning experience that prepares you for the challenges of managing laser safety in real-world situations.

Investing in your education and obtaining LSO certification through LSC enhances your credibility and marketability as a laser safety professional and helps ensure that your organization maintains a safe and compliant working environment.

Take action when an accident or non-compliance issue arises. Take proactive steps to protect your workforce and ensure compliance by enrolling in Laser Safety Certification programs today. Visit our website to learn more about our certification courses and start your journey toward becoming a certified Laser Safety Officer.

How we can help now that you know?

If you need a designated laser safety officer or for more information about industrial laser safety, check out our courses for Industrial Laser Safety and Industrial LSO certification. At $149 our course is a bargain AND you can bundle with the LSO Kit for only $349 to set up your company’s laser safety training program. We also have an FAQ section with common answers about our courses, certification options and kit offerings. Click here for more information and get compliant today!

We also have healthcare/veterinarian and cosmetic specific laser safety and Laser Safety Officer certification courses available; you can check them for more details at Cosmetic Laser Safety and Cosmetic LSO Certification, and at Healthcare Laser Safety and Healthcare LSO certification. Get started today by enrolling your company. You can always email us at info@lasersafetycertification.com if you have any questions.

References

OSHA Laser Hazards: https://www.osha.gov/laser-hazards/standards

OSHA Technical Manual: https://www.osha.gov/otm/section-3-health-hazards/chapter-6

Can the LASER Safety Officer also be the LASER operator?

Absolutely; in many smaller organizations they are one and the only. Our LSO curriculum includes all of the Operator modules for just this reason.

Why yes they can. The LSO role is typically performed in additional to other duties. The Laser Safety Officer is typically a person who is already involved in safety program or the training of other staff. It is also common in many organizations for the LSO to also be a senior staff member, or a lead operator or technician.

Comments are closed.