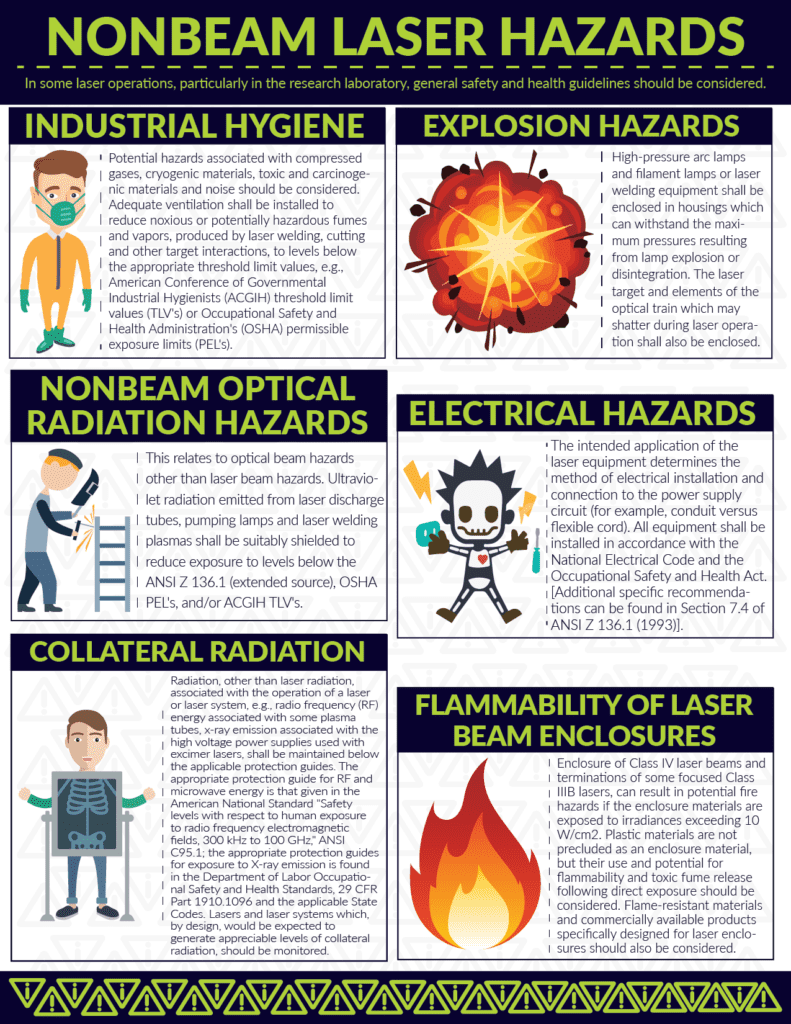

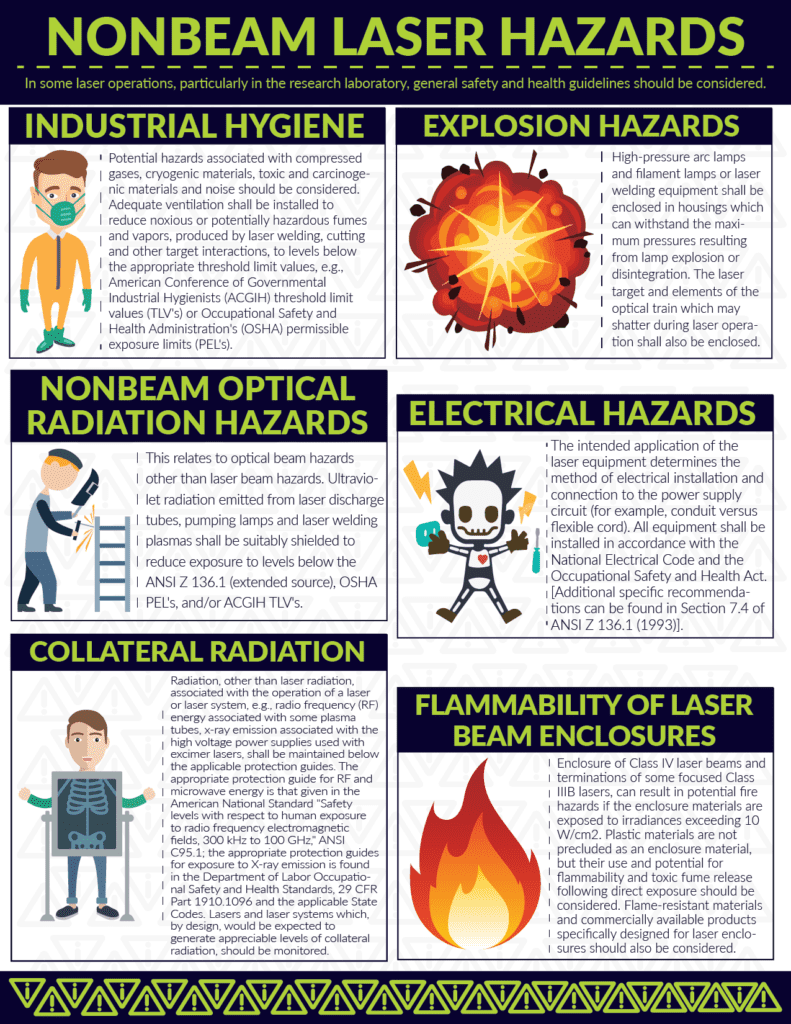

Non-beam Laser Hazards for Laboratory, Industry and Healthcare Users

Non-beam Laser Hazards in the Workplace

There are numerous non-beam laser hazards in the workplace. They co-exist with other more commonly known laser device operation safety issues and are just as important for workplace safety. A proper laser safety program will include the mitigation of non-beam hazards along other laser safety issues. Common non-beam laser hazards can be grouped into the following categories:

- Industrial Hygiene

- Explosion Hazards

- Non-beam Optical Radiation Hazards

- Electrical Hazards

- Collateral Radiation

- Laser Beam Enclosure Flammability

Industrial Hygiene deals with potential hazards from compressed gasses, cryogenic materials, toxic and cryogenic materials as well as noise. Adequate ventilation should be used to reduce fumes and vapors below appropriate threshold limits defined by the OSHA Permissible Exposure Limits (PELs) [3].

Explosion Hazards are related to lamp explosions or disintegration of high-pressure arc lamps, filament lamps and laser welding equipment. These should be enclosed in housings that can withstand the maximum pressures resulting from lamp explosion or disintegration.

Non-beam Optical Radiation Hazards are those other than laser beam hazards. For example, ultraviolet radiation from laser discharge tubes, pumping lamps and laser welding plasmas should be suitably shielded to reduce exposure levels below ANSI Z 136.1 [1], OSHA Permissible Exposure Limits (PELs) [3], [4] and/or ACGIH Threshold Limit values (TLVs) [2].

Electrical Hazards can be introduced due to the incorrect installation and connection to the power supply circuit. All equipment should be installed in accordance with the National Electrical Code (NEC) and the OSHA act, along with specific recommendations from ANSI Z 136.1 Section 7.4 [1].

Collateral Radiation other than laser radiation, that is associated with the operation of the laser or laser system, shall be maintained below applicable protection guidelines and should be monitored. The appropriate protection guide for RF and microwave energy exposure is from IEEE / ANSI C95.1 [5]. The appropriate protection guide for X-ray emission is found at OSHA Standard 29 CFR Part 1910.1096 and other applicable state standards [6].

Flammability of Laser Beam Enclosures can result in potential fire hazards due to the enclosures of Class 4 laser beams and the terminations of focused Class 3b lasers. Flame-resistant materials and commercially available products specifically designed for laser enclosures should always be considered.

These are just the highlights of the infographic above, if you would like a copy of it reach out to us at info@lasersafetycertification.com and we will send a copy to you. We have other laser safety infographics on other blogs in this series, so please check them out too.

About Laser Safety Certification

At Laser Safety Certification, we have laser safety courses and Laser Safety Officer (LSO) certification programs to make sure your team are correctly using lasers and your customers are protected. We provide certification programs that follow the OSHA recommendations and ANSI guidelines for laser safety. This infographic is a small part of that. We can help with your laser safety training needs if you are using lasers in manufacturing or production applications, or if you are using them in the medical, veterinary, cosmetic or healthcare fields and have concerns about your patient safety.

For more information about industrial laser safety, check out our courses for Industrial Laser Safety and Industrial LSO certification. For more information about medical, health care, or veterinary laser safety, check out our courses for Healthcare Laser Safety and Healthcare LSO certification today. For cosmetic laser safety, see our Cosmetic Laser Safety and Cosmetic LSO Certification courses for more information. We also have an FAQ section with common answers about our courses, certification options and kit offerings for your LSO to manage your own safety program.

Sources

[1] ANSI Z136.1: https://webstore.ansi.org/Standards/LIA/ANSIZ1362014?gclid=EAIaIQobChMI4PXoj87b-QIVghh9Ch0OrAReEAAYAiAAEgJakvD_BwE

[2] ACGIH TLVs: https://www.acgih.org/science/tlv-bei-guidelines/tlv-chemical-substances-introduction/

[3] OSHA Annotated PELs: https://www.osha.gov/annotated-pels

[4] OSHA Annotated PELs, Important Note Regarding the ACGIH TLV: https://www.osha.gov/annotated-pels/note

[5] IEEE / ANSI C95.1: https://webstore.ansi.org/Standards/IEEE/ieeec952019

[6] OSHA 29 CFR Part 1910.1096: https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.1096